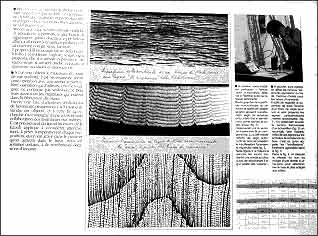

The importance of the measurment of sound velocity is that it gives the possibility to know when to cut the tree and which part of the wood will reveal the best sound properties. (Figure 5)

After having selected the best trunk in relation to its longitudinal velocity, we can optimize the cut of the trunk by also measuring the radial velocity. This represents the main criteria for making bowed instruments. (Figure 6)

|

In the graph, representing a trunk, an improper cut which doesn’t take into account the different transversal velocities, may damage an excellent material. After having completed measurements with the Lucchi Meter (also know as LucciMeter), it is possible to decide the best use of the material. A decision may be made (Figure 7), from the beginning, to determine the outcome of the level (student to professional) of the finished instrument.

|

Approximately twenty years ago, “Fazioli Pianoforti” showed interest in Giovanni Lucchi’s research by using the first version of the ultrasonic meter. Fazioli Pianos began to choose and classify in quality levels the construction materials they used in building their concert grand pianos.

The Lucchi Meter, in fact, enabled Fazioli Pianos to select and purchase the highest quality wood in order to acquire the best suitable material for high-grade concert pianos, leaving the inferior quality materials behind.

The quality of an instrument or bow may be decided before starting to work. Time is saved and the value of the finished product is increased. (Figure 8).

8) Publication of Fazioli’s study